Building Fiber Networks Through Software

Building Fiber Networks Through Software

One of the most long-lasting decisions construction companies and network providers will make is the selection of tools to design, build, document, and maintain fiber networks throughout their existence. Cost and evolving requirements make selection a tense process, especially since the projected utility of the software and data optimally bookends the very first network diagrams through the last day of operations.

Fiber Forward spoke with two network software design and construction firms to get their perspectives and insights into how an all-digital approach is essential for efficiently and effectively building and operating fiber networks throughout their lifecycle. While early fiber networks were designed manually and built using paper blueprints and punch tickets, the combination of geographic information systems (GIS), cloud computing, and mobile devices have changed back office and field processes for the better, lowering cost and build times.

“The construction industry in general has been paper based for 100 years, and in large part remains so,” said Robert Laudati, Chief Product Officer, Render Networks. “When you think about the benefits of software, it really boils down to two issues. One is digitization of the paper process, and the ability to capture the information that goes into a build, to record that accurately, and make it available for the actual operations of the network. There are miles of documentation around the gap between building these capital projects of networks and then not having the information available.”

The distance between what is properly documented and available compared to what is actually put into the ground ultimately leads to cut lines and disruption of core services with service providers more precisely rediscovering what is in the ground and installed in cabinets as they operate and repair the network and turn up customers.

“What we’re really all about is automating and optimizing that process,” said Laudati. “The desire and need to get to market first or second to capture customers is a critical issue. Labor costs are going through the roof. Automating [the build process] as much as possible and moving through the build as efficiently as you can is becoming the goal of many companies and that’s where a software approach enables that kind of scalability.”

For service providers embracing software as a tool to model and increase construction efficiency, Render is seeing an evolution from straightforward planning and design to more sophisticated economic modeling considering multiple variables.

“What we’re seeing play out in the industry is a very high-level financial feasibility assessment,” Laudati said. “It’s not a design yet, it’s a ‘Where should I go and how should I deploy a network? Should it be an aerial focus, because it is a rural area and houses are spread out? Is it urban, so I can go underground and really optimize the cost of going underground? Then, what is the offer that I need to provide to be appealing to customers?’”

Savvy service providers are working through deployment options first digitally, then going out into the field to get ground truth to verify their assumptions, refining their initial models with more detail, with Render involved towards the end of the design stage.

“The goal is to use these tools and processes to get to about 80% to the build,” said Laudati. “Render comes in as the network construction management process, a category we think is very distinct from the planning and CAD design drawing. And on the backend, once the network is built, we straddle the move from build to operations.”

Service providers typically run fiber to the curb into neighborhoods, then wait for subscribers to call in to be connected to service, a workflow that is often the same as initial construction process and same field crews, but the work ticket generated by a provisioning or BSS/OSS system that generates the service order to provision the service for each location.

“Our philosophy and approach are that the different stages of the [network] lifecycle be connected up,” said Steve Tongish, Chief Marketing Officer, IQGeo. “Having a unified shared geospatial model is really important. What oftentimes happens is people might have an app for this, an app for that, and an app for the other function and connecting those together can be quite challenging technically and operationally. You run the risk of losing data in the process.”

Automating Workflows from Design through Construction

IQGeo presents a couple of different ways to conduct network planning and design. For large greenfield builds, it has automated tools that can conduct an initial high-level design, with the ability to manually do smaller areas and more detailed design for larger builds. The automated tool enables planners to define architectures, define routes and types, and generate full costing with multiple iterations to assess tradeoffs with different approaches.

“The nice thing about using the automated process is you end up with a very consistent design,” said Tongish. “We’ve seen that not only does it save a huge amount of time in the planning process, but you end up saving money on the backend during construction. If you’ve got three, four, five designers working manually, you won’t have the design consistency, which costs you more money when you go to build it.”

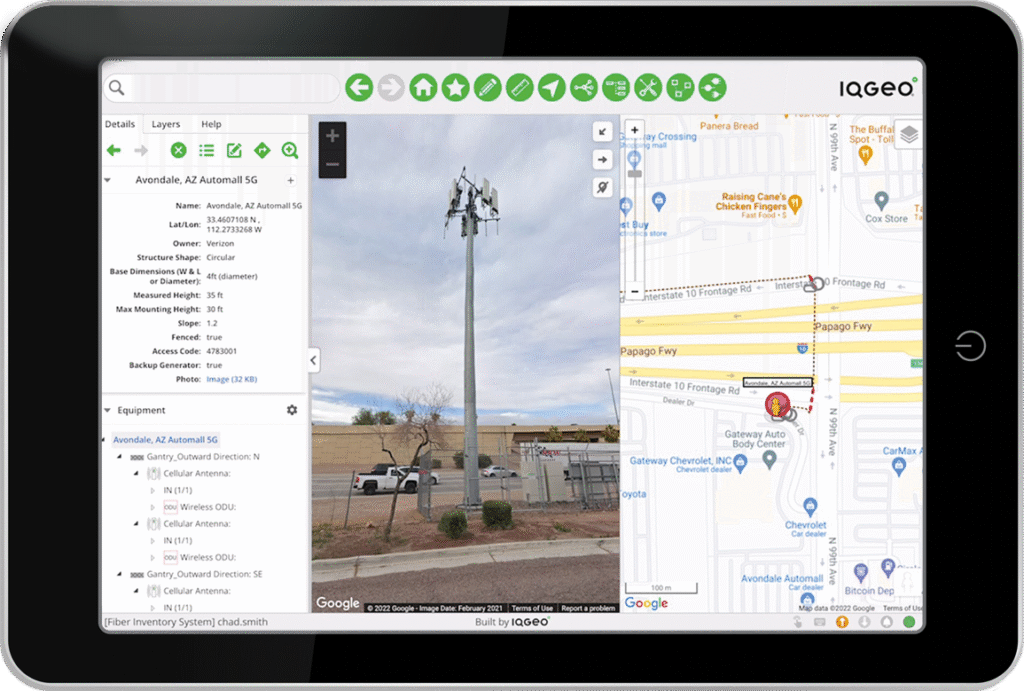

What’s in the cabinet? Thanks to network construction software, technicians can pull up the latest documentation on what should be at any location and pictures from the last visit. (Source: IQGeo)

Those plans can then be generated for field validation and then moved into construction.

IQGeo provides a workflow automation tool that creates the construction process as well as various integrations into existing processes. Render believes that the managing process of network construction is where it shines relative to any other option on the market. “At build time, we’re not changing the design, we’re changing how it gets built,” said Laudati. “We create an optimum order of work instructions that takes into account a variety of issues, including the network connectivity that’s expected, labor availability, materials availability, and ultimately permits if they’re available at the time of ingest. We can model different scenarios around that, depending on where you have funding or labor that can change your work order.”

Render’s software is designed to optimize build processes to avoid dependency bottlenecks that will tie up field crews and releasing work when all resources are available, with the ability to create dynamic work orders as conditions change and updated knowledge from the field results in changes as the build advances. Both firms also emphasized the ability to document the build immediately as work is completed.

“As construction commences, field crews can capture the as-built information that goes straight back into the model to be shared and used for long-term operations and maintenance,” said Tongish. “One of the things we do extremely well is support field operations. People can go into the field with the right workflows, so they can do things like design verification, surveys, or inspections. When the field crew goes out and validates that design, making sure that in fact the environment is as it was described during the design process, when you get to construction it can go smoothly. Then you capture the network as-built and so on.”

But software has to be usable in harsh field conditions on the devices field teams have available to them. “Unless the field teams adopt the software, you have no data to work with,” said Laudati. “Making sure that the mobile solution is fit for purpose for the construction industry is worth highlighting. That’s a particular type of user who’s got a lot of responsibilities out in the field. They typically have a phone with them, but they don’t have it in hand all the time. There has to be a really ergonomic user interface so they can get in and out quickly for simple tasks and workflows so they can complete the information and not spend a lot of time on the phone. They’ll have gloves on, they’ll have splicing glue on their fingers, they’ve got other things that they’re working on.”

Network construction software needs to be designed for field routines and equally usable on a tablet or phone, with the tablet a preferred device by many. (Source: IQGeo)

Verifying and capturing data throughout the build process provides construction crews, primary contractors, and the service provider with “a single source of network truth,” said Tongish, uniting different people and processes through centralized record-keeping. The unified geospatial model enables third-party information to be layered in on top of it, including keeping track of field crew locations and repair assets and monitoring weather impacts. In addition, APIs can import fiber testing data generated by IQGeo partners to provide still more documentation and detail on the build history and status of network infrastructure.

“This is a huge asset for contractors,” said Tongish. “They want to get paid when they complete their jobs. We provide the tools to confirm that these things have been done and done correctly. They then can be paid promptly and properly and that’s good for everyone. We use that same workforce principle for other operational tasks, planned and unplanned maintenance tasks, whatever it is, you can use our generic workflow tool to build workflows to any number of operational tasks, again, directly linked to a unified model.”

Like most vendors these days, IQGeo can be accessed either via the company’s own cloud or deployed on-premise for larger customers that prefer to have the software in-house and on-site. “The reason why Tier 1, Tier 2 operators do [on-site], they have very complex environments,” Tongish stated. “They might have acquired a bunch of companies. They have all kinds of systems, they might have multiple old legacy GIS running around, they just have a complex ecosystem of technology. But interestingly enough, we are seeing some of those big Tier 1 and Tier 2s looking to simplify their life, reduce that IT technical debt and go to cloud deployments.”

Integration of other data into IQGeo is done through a FME environment and FMV integration, while a documented set of developer APIs enable customization and integration with other systems, including enterprise GIS platforms. For example, aerial drone surveys used to identify and assess the status of pole and vault locations could be processed and then imported into IQGeo, and satellite imagery could be added for vegetation management purposes.

“We’re pretty data agnostic,” said Tongish. “We’re happy to bring the data in. We can usually find a data import mechanism for third-party data, they’re the guys who know how to capture the data.”

Adding AI and other benefits

New features IQGeo have added emphasize the service operator’s shift beyond network planning and design to increasing value and efficiencies on the operations side. Major operators are focused on the monetization of their fiber networks, especially in competitive markets. The company’s Network Revenue Optimizer tool enables service providers to respond very quickly to connectivity requests while optimizing fiber build paths to add additional prospective customers.

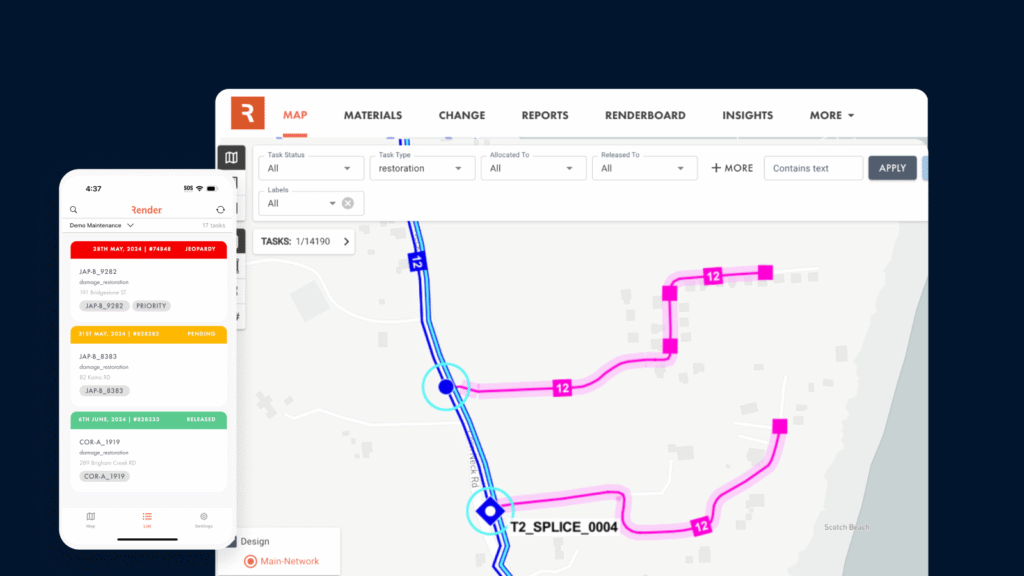

Once network construction is completed, the field data collected in the build and closeout can be used during the lifetime of the network for routine maintenance, updates, and expansion. (Source: Render)

“It’s to make sure service providers are getting the maximum revenue that they have in the ground and focused generally on business-based applications,” Tongish said. “For example, a new chain may come into town and want broadband connections to their eight new locations. The tool allows the service provider to look at its current network and say, ‘OK, we can hook up these locations right away because we’re right out their door. The other ones, we’ll have to run fiber to them, but when we go down this street, let’s check Dun and Bradstreet [economic data] to see if there are other businesses we might be able to monetize along the way.’”

AI is being brought into the discussion through IQGeo’s March 2025 purchase of Deepomatic, a computer vision software company. Deepomatic dynamically analyzes the photography field crews take to make sure that the job is being done and documented properly, as well as looking at other parts of the network while the crew is out there.

“It’s a multi-stage approach,” said Jay Cadman, Senior Vice President, IQGeo. “As an example, if it’s a splice closure, we’ll analyze not just the splice the technician hit, but the other splices that are included in there and compare it to the system of record. If there’s a mismatch, then the AI will flag it so an engineer can go in and make those changes.”

AI provides checks to make sure the photos are clear and for staff potentially gaming the verification system by reusing the same photography. At the end of the day, field photos can be blurry or not centered due to human error, leading to temptations to substitute in a clearer picture of an earlier job to close a work ticket. In a few moments of analysis, the software makes sure the photo is of sufficient quality and original, then updates the system records accordingly.

Render also sees AI adding additional virtual eyes to workflow. “A lot of AI is starting to come into play around measuring work, taking pictures of the construction, restoration, test results and analyzing and make sure it is valid before the crew leaves the field,” said Laudati. “So you have some efficiency gains by making sure the job is done right at the time of construction and not having to send a crew back two days later to correct errors.”

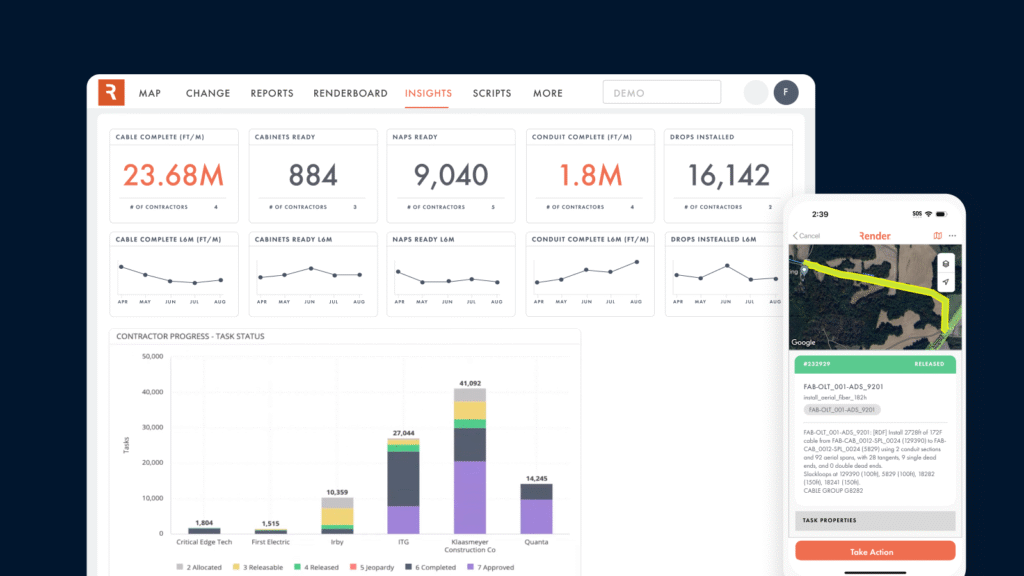

A centralized dashboard for network construction provides real-time status of the build, which can be used for strategic decision-making and adjustments during the build process. (Source: Render)

Automating approvals using AI is expected to reduce the use of experienced personnel who would normally be involved in reviewing work across multiple field crews. Other features that have emerged over the past few years include the ability to forecast builds based on documented performance data and being able to reassess financial and build decisions while networks are being constructed.

“You can use the information you have within these systems to forecast the completion of different portions or the entirety of the network,” said Laudati. “We can gather productivity data, then use that against the remaining work that needs to be done. You can see, based on your current progress, the availability of current crews, and current productivity rates if you are going to achieve your construction goal. If you aren’t, you can look at what you can do to get back on track by adding more crews and/or changing processes.”

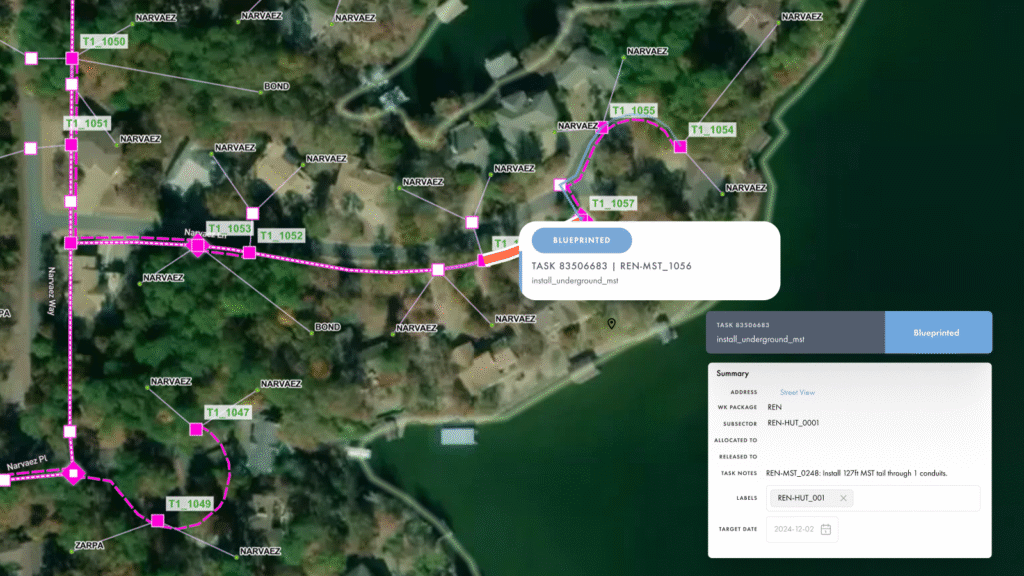

Network construction software can provide build status and task orders for construction and repairs and provide an overview linked to geographic location. (Source: Render)

Render is finding its customers are conducting more real-time project analysis, adjusting to market conditions. “In a two- or three-year project, build scenarios can change when a new competitor arrives or the economic dynamics of the service area has changed,” Laudati said. “Organizations are getting more agile with their construction. With new competitors arriving, it may not be worth building where they initially planned and it makes sense to shift resources over to a different area.”

Taken together, these vendors have illustrated a new paradigm for bringing a traditionally paper-based construction process to a digital and automated one. Clearly, building fiber networks through software has a number of benefits, particularly given the current environment of high costs, stiff competition, and continuing supply chain challenges.